From Submarines to Fighter Jets—Repairing DOD’s Vast Array of Weapon Systems

DOD’s repair depots ensure that critical weapon systems like aircraft, submarines, and tanks are ready for military operations. But if these depots can’t complete maintenance on time, DOD’s weapon systems can’t be used for operations and training.

So, how are DOD’s maintenance depots performing, when it comes to completing maintenance on time?

Today’s WatchBlog takes a look.

The Navy’s struggles

The Navy is struggling to complete maintenance on time for its fixed-wing aircraft, aircraft carriers, and submarines.

For example, Navy depots were overall late completing select fixed-wing aircraft maintenance every year between FYs 2014-2019, completing maintenance on time about 50 percent of the time. Navy aircraft have spent over 62,000 more days in maintenance than expected since FY 2014. We recommended (among other things) that the Navy identify more accurate turn-around target times for aircraft maintenance.

Additionally, the Navy’s 4 shipyards completed maintenance on time for aircraft carriers and submarines just 25% of the time from FYs 2015-2019. The two main causes for the delays included unplanned work and issues with shipyard workforce performance and capacity, which resulted in the Navy relying on excessive use of overtime to attempt to address these issues. We recommended that the Navy address workforce requirements to avoid the excessive use of overtime. The photos below show a Navy F/A-18 and a submarine undergoing depot maintenance.

Image

Image

Air Force, Army, and Marine Corps depots

The Air Force, Army and Marine Corps have generally met their depot maintenance goals in recent years.

The Air Force’s depots completed aircraft maintenance on time or early 78% to 90% of the time between FYs 2014-2019. This was partly due to frequent communication between program offices and depot stakeholders.

The Army’s depots reported meeting their maintenance goals for about 91% of weapon systems in FYs 2018 and 2019. However, we found that the Army’s metric for meeting maintenance goals could be improved and that the Army experienced many changes to its planned workload. We made 4 recommendations to the Army, including that it could better plan workflow at its depots.

The Marine Corps’ depots also reported that theygenerally met maintenance goals for FYs 2015-2019. However, the Marine Corps metric for meeting maintenance goals doesn’t assess performance against original goals and doesn’t include all of its planned work.

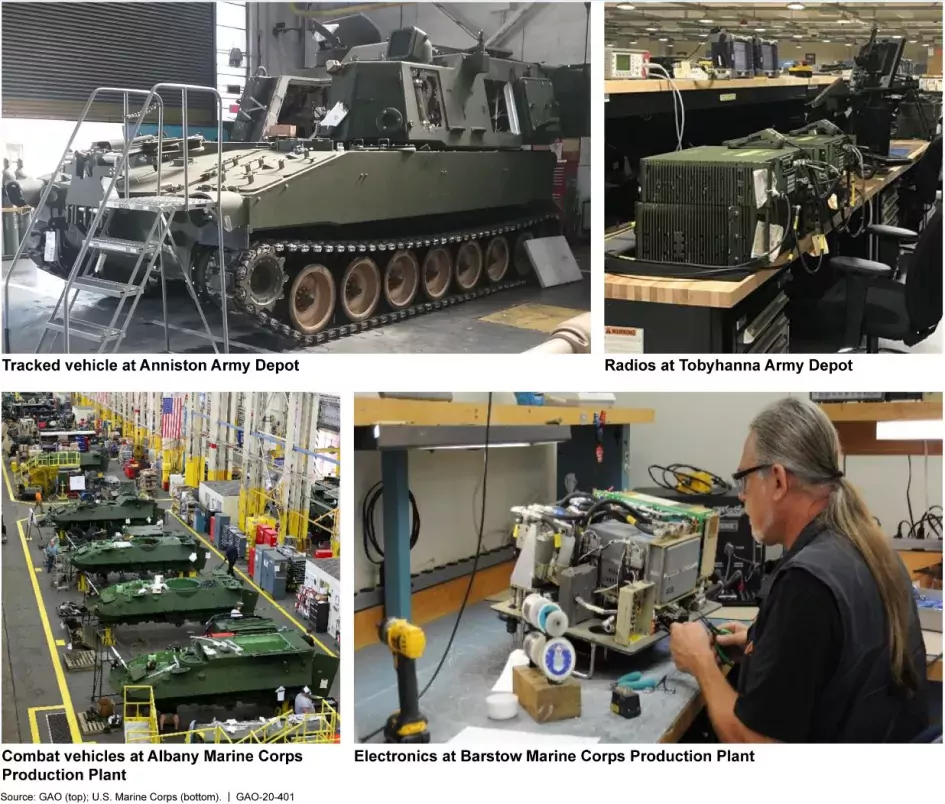

The photos below show Army and Marine Corps weapon systems undergoing depot repair.

Image

Lessons learned

While DOD’s depots have struggled to meet repair needs in recent years they have reported benefits from sharing best practices and lessons learned with each other. For example, one depot shared an improvement for a type of aircraft gearbox that reduced repair time from 95 weeks to 4 weeks.

DOD could do more to help depots share information—like creating a comprehensive list of depot working groups.