Science & Tech Spotlight: Consumer Electronics Recycling

Fast Facts

Consumer electronics contain gold, platinum, rare earth metals, and other high value materials. Domestic recycling of electronics could reduce the U.S. reliance on imports of these materials.

However, electronics recycling is complex and faces challenges, such as a lack of profitability. Electronics require disassembly by hand or shredding and separation.

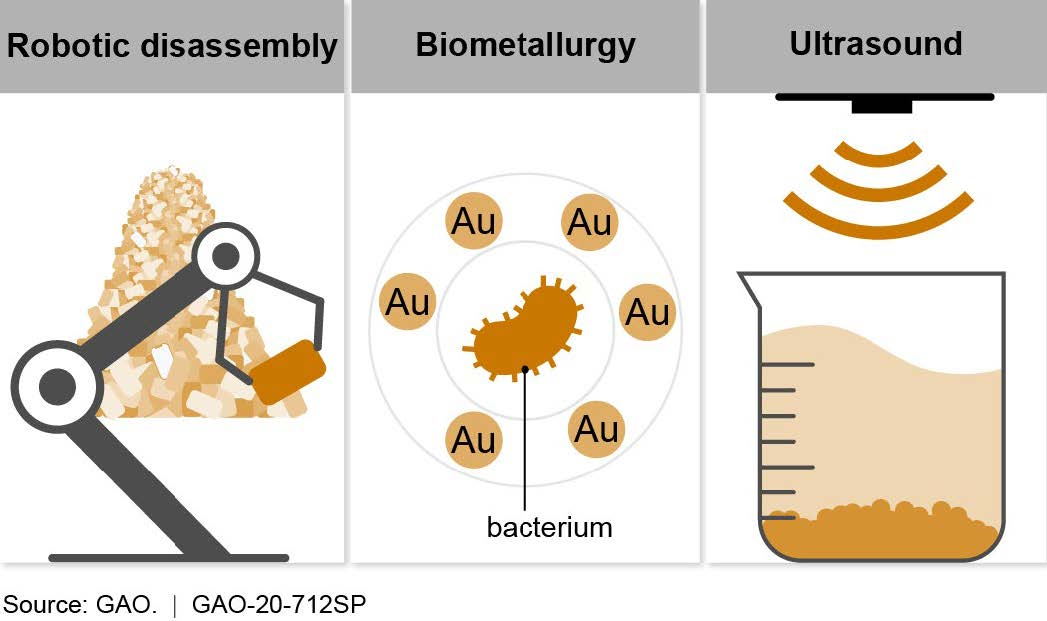

Emerging technologies could make it easier. For example, a manufacturer is piloting robotic disassembly for its products. Ultrasound is now widely used as a separation technology and new microorganisms are being developed in laboratories to separate high value materials in electronic waste.

Highlights

Why This Matters

Consumer electronics contain critical materials whose supplies are limited, including gold, platinum, and rare earth metals. Domestic recycling of consumer electronics could extend the supply and reduce the current U.S. reliance on imports. New technologies are becoming available, but electronics recycling is complex and faces challenges, such as narrow profit margins.

The Technology

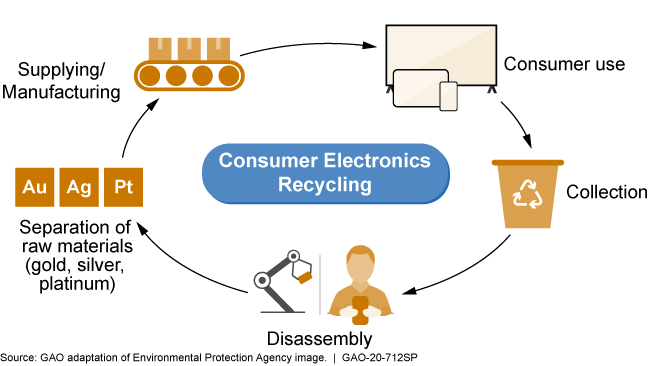

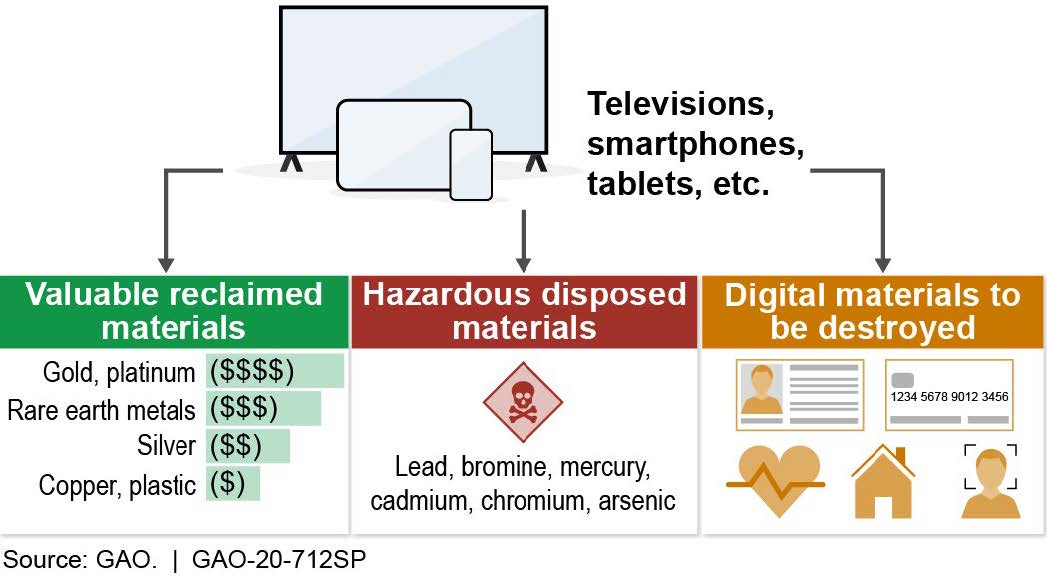

What is it? Recycling of consumer electronics—including smartphones, televisions, and computers—generally involves separating high-value metals from plastics and other low-value materials. Precious metals and rare earth metals are the economic driving force for consumer electronic recycling technology. These metals have high market values and limited supplies, and they can be reused across many industries, including the defense and energy sectors. Consumer electronic devices can also contain personally identifiable information (PII), including medical and financial data, which could be improperly disclosed if they are not destroyed prior to recycling. According to a study of selected consumer electronics, about 2.8 million tons were disposed of in the U.S. in 2017, of which about 36 percent was recycled.

Figure 1. Selected valuable, hazardous, and digital materials contained within consumer electronics that can be recovered, disposed, or destroyed

There is no federal standard requiring consumer electronics recycling. Some states have enacted electronics recycling laws requiring electronics producers to pay fees or contract with businesses to ensure electronic waste is collected for recycling. The U.S. recycles electronics domestically and also exports electronics for recycling abroad.

How does it work? The high concentration of valuable material in certain consumer electronics is key to the economic viability of recycling these products. Cell phones, as one example, have more precious metal by weight than raw ore does. According to the EPA, 35,274 pounds of copper, 772 pounds of silver, and 75 pounds of gold can be recovered from a million recycled cell phones. Based on commodity market prices on August 12, 2020, these weights of metals are worth approximately $100,000, $290,000, and $2.1 million for copper, silver, and gold, respectively. In contrast, cathode ray tube (CRT) displays in older televisions and computer monitors have little recycling value, but they contain leaded glass and may be considered hazardous waste. In addition, recovery of certain valuable materials from consumer electronics is limited due to the high costs of technology and processing.

Electronics recycling companies disassemble devices by shredding, which also destroys PII, or by hand. These companies then separate valuable materials for reuse (including gold, silver, platinum, and rare earth metals) from toxic materials for disposal (including brominated materials and lead). Traditional methods include burning to remove non-metal parts and separation using strong acids.

New separation technologies are being used or piloted to recover precious and rare earth metals. For example, robotic disassembly uses machine learning and computer vision to more rapidly pick and sort items. Another new technology uses ultrasound to speed up the chemical removal of gold from cell phone SIM cards.

Figure 2. Emerging separation technologies for recycled electronics

Other technologies are emerging, like biometallurgy, which uses microorganisms to separate high-value metals from other materials, such as plastics, glass, and glue. For example, naturally occurring bacteria can oxidize gold in acidic solutions, making it soluble and thus easier to separate from other materials.

Other advanced techniques, such as magnetic or electrochemical separation, are showing promise in the laboratory with existing technology. For example, in one study, researchers used ultrasound to dissolve nickel and gold within a SIM card. They then used a magnetic field to separate the dissolved nickel, which is magnetic, from the gold, which is not. Similarly, other techniques use electric fields to separate dissolved metals based on their weight and electric charge.

How mature is it? Recycling technology is well established for some traditional single-stream processes, such as aluminum recycling. However, electronic devices are more complex and require disassembly and separation. At least one consumer electronics manufacturer is piloting robotic disassembly for its products. Emerging separation technologies such as ultrasound have come to market in the past decade and are being used. Manual disassembly and shredding are decades old. Biometallurgy is being tested in pilot plants, and new microorganisms are being developed in laboratories to treat electronic waste.

Opportunities

- Increase supply and reduce imports. Recycling could increase the domestic supply of precious and rare earth metals and reduce the current U.S. reliance on overseas sources.

- Grow the green economy. Developing advanced recycling technologies could promote domestic business and employment.

- Reduce hazardous practices. A significant amount of recycling currently occurs in the developing world, where methods include open-pit burning. New technology could reduce the use of such methods, which are hazardous to the environment and human health.

- Lessen environmental impacts. Developing advanced recycling technologies could reduce the environmental impacts of raw ore mining and landfill disposal of hazardous materials such as lead and brominated materials.

Challenges

- Market challenges. Markets for recovered materials may be limited, and the value of recovered materials may not be enough to cover the costs of equipment for collection, sorting, disassembly, and separation.

- Secure destruction of personal information. Many electronic devices contain PII. Shredding them may effectively destroy PII but may also make high-value material harder to recover.

- Counterfeit electronic parts. Exported used electronics may serve as a source of counterfeit electronic parts, which, as GAO previously reported, could disrupt parts of the Department of Defense supply chain and threaten the reliability of weapons systems. (See GAO-16-236, linked below.)

- Rapid technological development. As consumer electronics made with new materials get smaller, new technologies for separation may be needed to recycle valuable materials.

Policy Context and Questions

With the volume of electronic waste expected to grow, questions include:

- How can programs to support technological innovation, economic development, and advanced manufacturing be leveraged to promote a more robust domestic electronics recycling industry?

- What efforts can the federal government, states, and others make to incentivize recycling rather than disposal? What are the potential benefits and challenges of such policies?

- What strategies can the public and private sectors implement to address the risk that exports of used electronics will contribute to unsafe recycling practices, disclosure of PII, and counterfeit electronics? How can reductions in exports bolster job growth?

For more information, contact Karen Howard at (202) 512-6888 or HowardK@gao.gov.